STEEL SURGERY SERVICE MEATALSTICHING based in INDIA HAVING A 33YRS EXPERIENCES is an established mechanical repair company. The company was established in the INDIA in 1997 and in the years that have followed we have built up an outstanding reputation for quality work delivered on time and within budget.

”Metal Stitching ” method is recognized as the best method to repair cracks,breaks and other damages to cast-iron, steel and aluminum castings. The biggest advantage of this method is lack of deformation and lack of thermal stresses occurred during welding. Moreover, in most cases, further machining is not required. Even complex cracks can be repaired during a short repair period.

The process is now recognized and used throughout the world. Cold casting repairs carried out by STEEL SURGERY SERVICES are superior to welding in case of crack sensitive materials.

THE Repair Procedure

Various steps for carrying out repair by this method are as under.

The fracture is positioned, realigned and firmly held together by special fixtures

and

clamps.

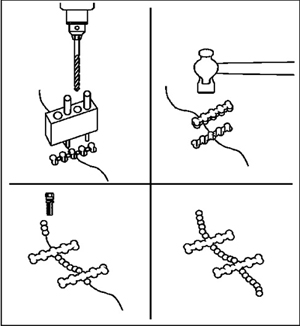

Jigs are used to drill groups of holes across the line of fracture to the depth of the casting

and the holes are joined to form the shape of MetaLLock Key.

Individual layers of Keys are inserted in the apertures and peened into a metal to

metal condition, which becomes almost integral with the parent metal of the component

under repair.

Holes are then drilled along the line of the fracture, tapped and filled with studs. Each

stud is fitted biting into its predecessor resulting in a pressure tight joint. This is the main

part of the process in which the crack is replaces by the stitching studs.

The surface is then peened and excess material is removed The repair is complete and

the component generally does not require further machining.

Advantages

-

The Met locking repair process is used successfully and recognized by the Classification Societies.

- In many cases the equipment gives many more years of productive service after repair.

-

Cold repair can be carried out to castings of cast iron, steel and non ferrous alloys.

-

Many repairs can be carried out onsite with minimal or no dismantling.

-

Downtime of equipment is minimized as the broken pieces can be put together to maintain alignment and original surfaces with little or no machining requirement.

-

A pressure tight seal can be achieved due to the interlocking between MetaLLock keys and studding.

-

Since the repair is done in a cold state, there is no distortion and residual stresses are not introduced.

-

The Key design is such that the load is gradually transferred from the Key to the casting.

-

This helps to dampen mechanical vibration and provides an expansion joint when temperature fluctuations occur.

MERILESS BLACKSTONE DIESEL ENGINE 4.3 MW .K- MAJORE. MK3.

MASTERLOCK describes a method of repair using an inlay of high-strength alloy plate. These plates are inlaid at points of high stress concentration in broken castings or in unbroken sections subject to overloading and subsequent fracture. MASTERLOCKS are held in place by dowels cold worked into matching half holes between the parent metal and the lock. The size and shape of MASTERLOCKS vary with the requirements of each repair.

INTERLOCK: is a variation of the MASTERLOCK. Holes of various designs are cut into the plate. When the parent metal is cut out to fit the form of the INTERLOCK, 'islands' of parent metal, which fill the holes in the INTERLOCK, provide additional strength in shear. This type of lock is generally used in weak castings or in steel where some advantage may be gained by utilizing the support of the parent metal more efficiently.

METALACE designates the method of sealing cracks against leakage. Holes are drilled and tapped and METALOY * studs or dowels are inserted tangent to each other along the line of fracture. The studs are cold worked to ensure tightness and complete filling of the crack with new metal. METALACE is used in conjunction with METALLOCKS to accomplish a pressure tight joint and to lend rigidity to all METALLOCK repairs.